Membrane Treatment Solutions

In addition to pre-treatment of feed water, protecting membranes from clogging due to dissolved salts and organics in the water is critical. Using the correct antiscalants, cleaning chemicals, and biocides in a Reverse Osmosis (RO) system helps optimize its operating efficiency, prevents failures, and prolongs the membrane service life.

Chembond Water Technologies offers high-performance products to help you operate your RO plant efficiently even with difficult feed water containing high levels of silica, phosphates, or sulfates. Our products will help maintain your system performance and product water quality at optimum levels, reduce operating costs by reducing energy requirements to maintain the required product flow, and will reduce your replacement costs by prolonging the membrane life.

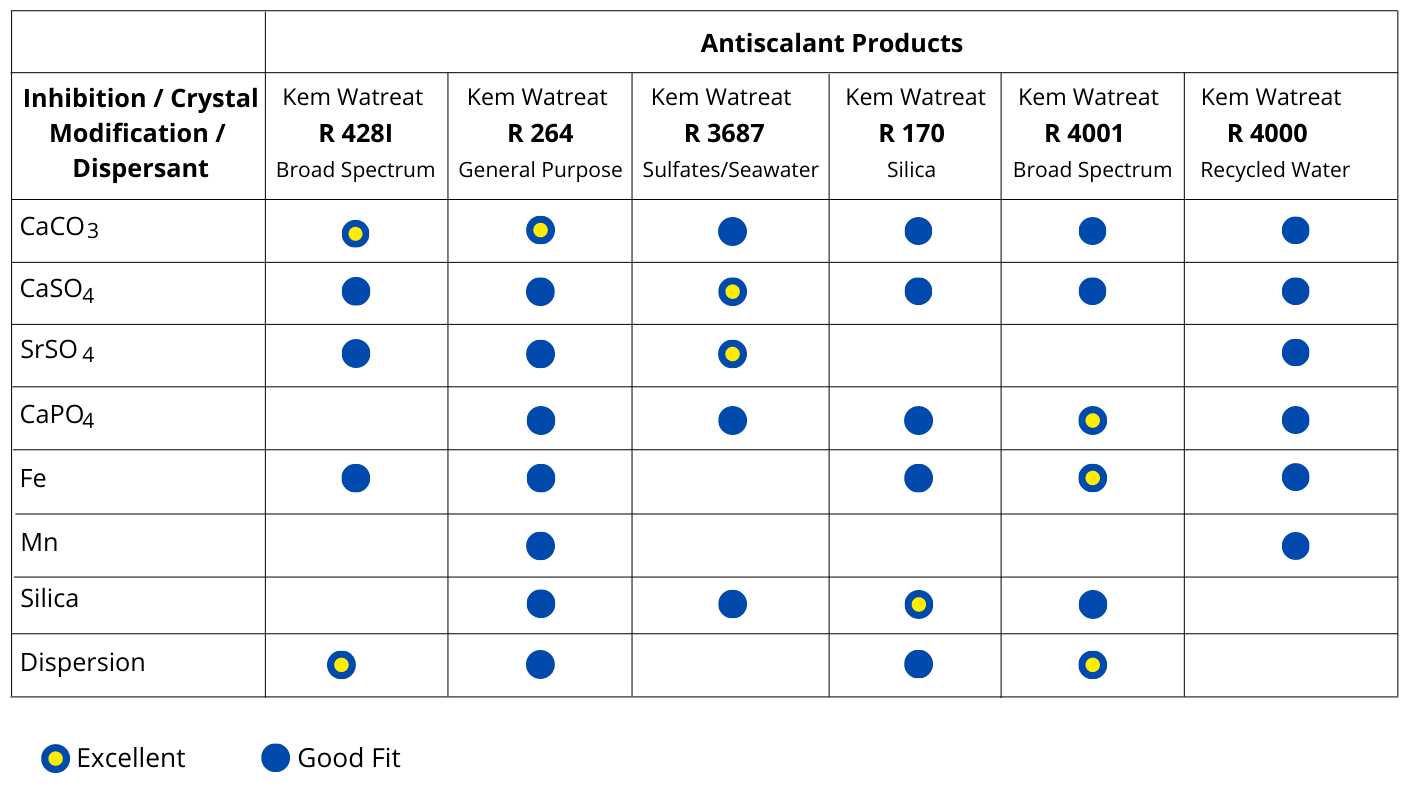

Membrane Antiscalants

Textile wastewater contains dyes in combination with a variety of contaminants. As environmental legislation requires textile mills to treat their effluent to meet discharge limits, coagulation and flocculation play a vital role in helping the mills meet this requirement.

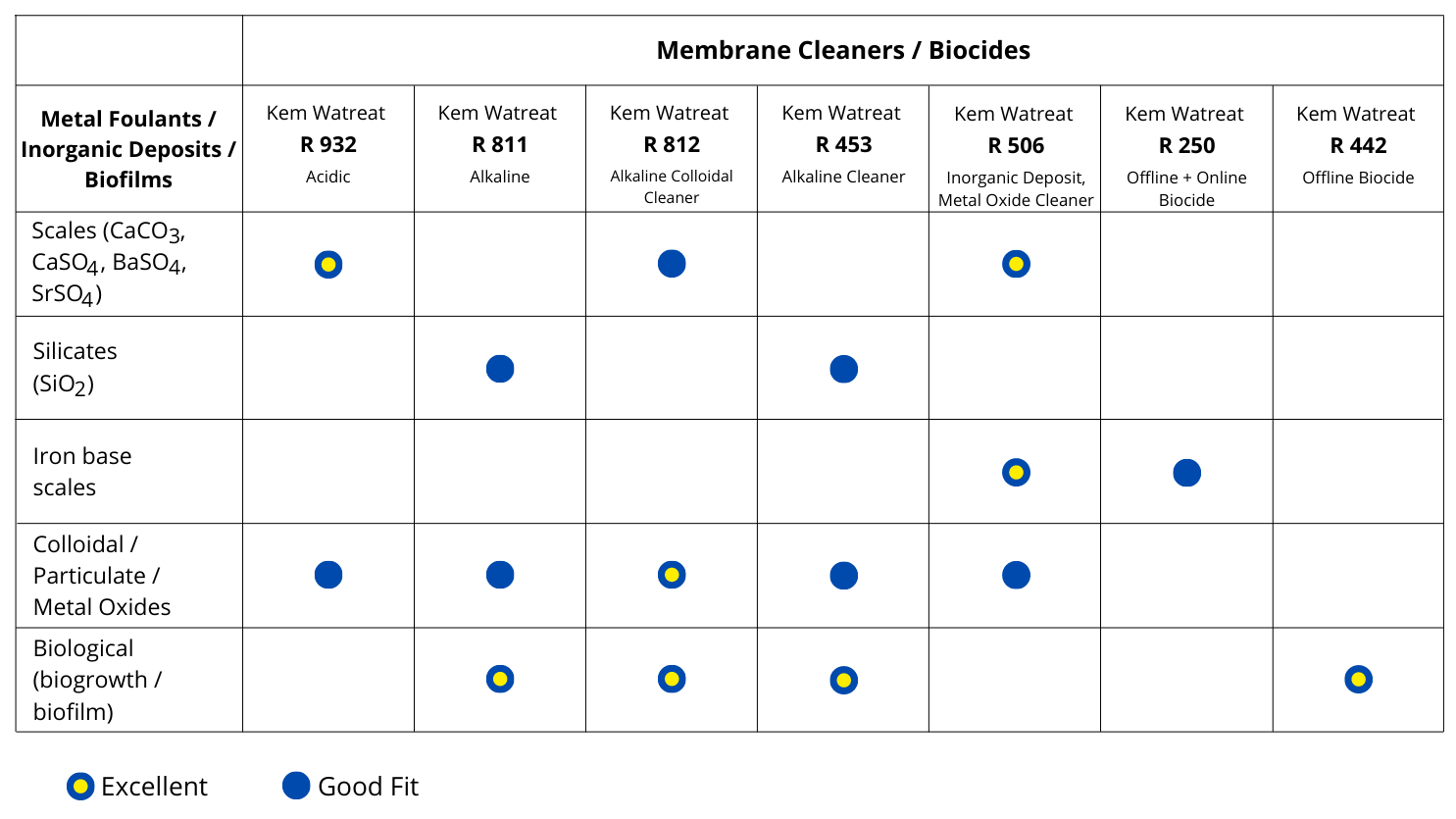

Membrane Cleaners / Biocides

Food processing industries generate wastewater with high biological oxygen demand (BOD) and chemical oxygen demand (COD). Amongst food processing industries, dairy processing industries pose major challenges to treatment of wastewater on two counts – the volume of wastewater generated per day, and the volume of wastewater generated per liter of produced milk (0.2 to 10 liters wastewater per liter of produced milk). Wastewater is generated right from the receiving station through milk bottling, cheese, butter, and ice cream production sections. The most important organic materials in the wastewater are fat, lactose and proteins (casein). Cream, butter, cheese, and whey production sections are the major sources of BOD in wastewater. Dairy wastewater can be treated by adjusting the pH and using chemical coagulants. The role of coagulants in dairy wastewater treatment is that of de-emulsification (break fat-water emulsions formed due to the use of surfactants, cleaning agents and sanitizers in the process), precipitation, coagulation, and flocculation. This crucial treatment enables the dairy industry to meet its wastewater discharge norms or to afford further treatment of the wastewater for recycle or re-use.

Kem MemPro Optimizer Tool

Kem MemPro software tool helps system designers optimize the antiscalant dosage for brackish water and sea water RO membrane systems. On entering the feed water parameter analysis, Kem MemPro calculates the fouling tendency and recommends the most appropriate antiscalant product and dosage. This helps immensely in optimizing the treatment program.