Chembond Water Technologies

Bonding Innovation with Technology

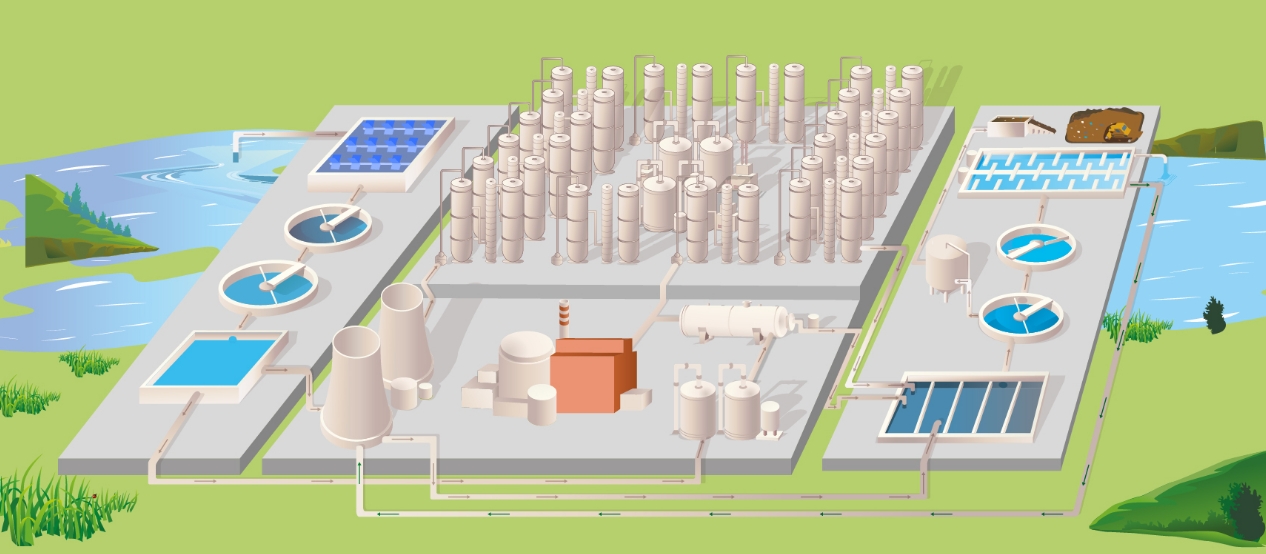

Chembond Water Technologies Limited stands as a pioneer of non-chromate cooling water treatment chemicals in India. Since the introduction of these products in 1980, we have continuously expanded our range to encompass a comprehensive suite of water treatment solutions. Our extensive product line includes boiler water treatment chemicals, membrane treatment chemicals, polymers for raw water and effluent treatment, as well as defoamers. We’re committed to holistic water solutions, investing in cutting-edge systems and advanced microbial remediation for high COD industrial wastewater. Our systems division, Chembond Clean Water Technologies, is a trusted subsidiary, offering turnkey water treatment and recycling solutions across industries.

Services Offered

We offer solutions for the complete range of water treatment, encompassing specialty chemicals, equipment, and wastewater remediation.

Awards & Accreditations

ISO 14001:2015

Environmental Management System

ISO 9001:2015

Water Treatment Chemicals